STANDING DRESSING TOOLS

The dressing of grinding tools that contain aluminium oxide or silicon carbide as abrasives must achieve the following:

- restore the concentricity and geometric shape of the grinding wheel

- restore the required surface roughness of the grinding wheel

- clean the cutting surface of the grinding wheel

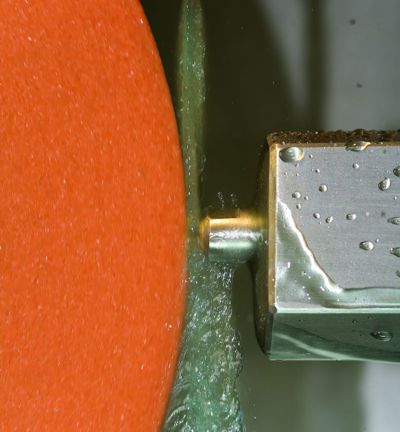

Suitable dressing tools are firmly clamped and guided. The dressing movements (feed rate and infeed) are performed by the dressing tool or the grinding wheel. The sequence of movements performed by the dressing tool determines the geometry of the grinding wheel to be dressed. Diamond is the most obvious candidate for dressing applications as it is harder and more wear resistant than all other materials.