FAST PRODUCTION OF COMPLEX PROFILES

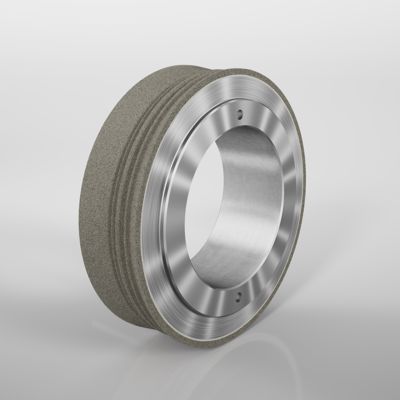

Profile dressing rolls

The dressing tool generates the profile by creating a groove in the grinding tool. The advantages of this process include rapid production of complex profiles in the grinding tool, low dressing cost per workpiece, fine surface qualities, and optimised utilisation of machine capacity. The main applications are to be found in the automotive industry and its suppliers as well as manufacturers of rolling bearings, drive technologies, turbines, precision tools, and machines.

Electroplated negative profile dressing rolls are manufactured to very tight tolerances. The production processes for these tools are more complicated than those for positive dressing tools. In practical applications, profile dressing tools manufactured using the negative process have a longer tool life. Negative profile dressing rolls are mainly used in the mass production of complex, high-precision profiles.

Path-controlled form dressing tools (CNC form rolls)

Path-controlled form dressing tools can be used to generate a variety of grinding wheel contours using just one tool. For different grinding wheel types, there are preferred manufacturing processes for the form dressing tool. Thus, it is possible to specify and control the dressing result over a wide range.

Positive electroplated form dressing tools are covered with a single layer of diamond. This creates a constant dressing width. These form dressing tools are used to profile ceramically bonded cBN grinding wheels, aluminium oxide and special aluminium oxide grinding wheels.

Negative electroplated form dressing tools and infiltrated designs are used for conventional grinding tools made from aluminium oxide and special aluminium oxide. The major difference here is that the infiltrated version achieves its high precision by the grinding of the diamond coating and the electroplated version through the production process. In addition, the achievable convex radii are different. In some cases, form dressing tools with small radii are also suitable for dressing ceramically bonded grinding wheels.